Information, Flyers & Common Trailer Questions

Downloads

- Dexter Axle Order Form (Print & Fill)

- Dexter Axle Order Form (Online Fill)

- Trailer Brakes Break-in Procedure

- How Car Mate Minimizes Electrolysis

- Car Mate Enclosed Trailers vs. Competition

- Car Mate Trailers Features

- Car Mate Trailers 4′ Wide Custom Cargo Trailer Enclosed

- Car Mate Trailers 5′ Wide Custom Cargo Trailer Enclosed

- Car Mate Trailers 6′ Wide Custom Cargo Trailer Enclosed

- Car Mate Trailers 7′ Wide Custom Cargo Trailer Enclosed

- Car Mate Trailers 7′ Wide Cargo Trailer Enclosed Contractor Trailer

- Car Mate Trailers 8′ Wide Custom Cargo Trailer Enclosed

- Car Mate Trailers Advantage Cargo Trailer

- Car Mate Trailers Enclosed Cargo Contractor

- Car Mate Trailers Enclosed Car Hauler

- Car Mate Trailers Popular Options

- Car Mate Trailers Enclosed Trailer Exterior Color Options

- Car Mate Trailers Sportster Enclosed Cargo Trailer

- Car Mate Trailers Sportster 6 & 7 Wide HD Enclosed Cargo

- Car Mate Trailers V-Sport 5, 6 & 7 Wide Enclosed Cargo

- Car Mate Trailers Open ATV Trailer and Lawn Trailer

- Car Mate Trailers Eagle Enclosed Care Hauler Trailer

- Car Mate Trailers V-Sport 6 & 7 Wide HD Enclosed Cargo

- Car Mate Trailers V-Sport and Liberty Sport Enclosed Trailer

- Car Mate Trailers Super Duty Enclosed Cargo Trailers

- Car Mate Trailers Sportster Enclosed Car Hauler Trailer

- Car Mate Trailer Angle Iron Open Utility Trailer

- Car Mate Trailers Angle Iron Open Landscape and Equipment Trailer

- Car Mate Trailers SST Open Utility Trailer

- Car Mate Trailers Open Utility AST Flyer

- Car Mate Trailers Contractor Dump Trailer

- Car Mate Trailers Open Car Hauler Trailer

- Car Mate Trailers Equipment & Hydraulic Tilt Trailers

- Car Mate Trailers Hydraulic Dump Trailer

- Car Mate Trailers DOW Equipment Trailers

- Car Mate Trailers Limited Warranty

- Car Mate Trailers Owners Manual

- Griffin Dump Trailers Wire Schematic

- Hillsboro Trailers Car Hauler

- Hillsboro Trailers Utility

- Load Rite Galvanized Open Utility Trailer Flyer

- Trailer Applications Manual by Dexter Axle

- Condor Pitstop Manual

- Condor Trailer Only Chock Manual

Diagrams

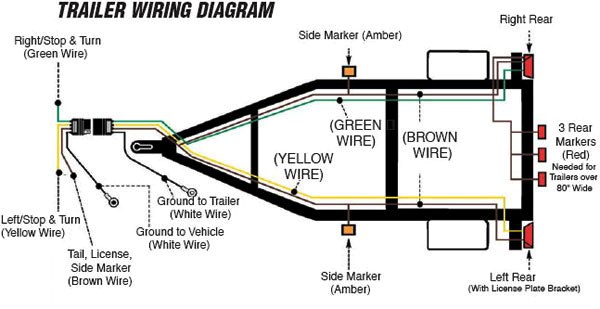

4-way Trailer Wiring Diagram

4-way Trailer Wiring Diagram

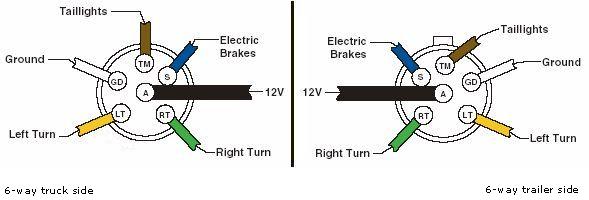

6-way Trailer Wiring Diagram

6-way Trailer Wiring Diagram

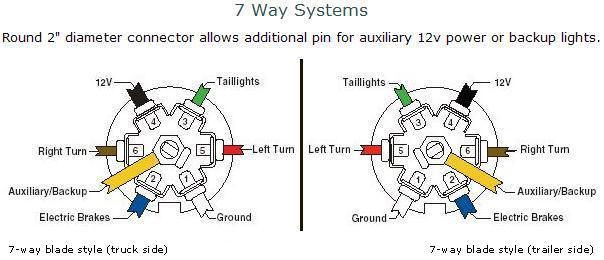

7-way Trailer Wiring Diagram

7-way Trailer Wiring Diagram

7-way Trailer Break Away Wiring Diagram

7-way Trailer Break Away Wiring Diagram

Common Trailer Questions

Q: Do I need to register my trailer?

A: All trailers are required to be registered in the State of New Hampshire, with the exception of yard-use only trailers. If it’s on the road it needs to be registered. Bring identification, proof of residency, bill of sale for the trailer, and the title or Manufacturer’s Certificate of Origin (if applicable) to your local Town Office to register your trailer after purchase.

In the State of New Hampshire you are also required to title your trailer if it weighs over 3,000lbs. and was manufactured after 2000. Trailers greater than 3,000lbs. GVWR require the former seller’s title or the Manufacturer’s Certificate of Origin and a bill of sale to title. If the Vehicle Identification Number (VIN) is not documented on the Bill of Sale, a completed VIN verification Form TDMV 19A is required. Trailers manufactured prior to 1999 are exempt from title requirements.

Q: Do trailers need to have a state inspection?

A: In the State of New Hampshire all commercial trailers are required to be inspected yearly. Additionally, all trailers with a registered GVWR of 10,000lbs or greater require yearly trailer inspections within 10 days after the end of the owner’s birth month.

Q: What is GVWR?

A: GVWR stands for Gross Vehicle Weight Rating. The GVWR is maximum amount of weight you can safely haul. This includes the empty weight of the trailer plus any cargo.

Q: What is the difference between GVWR, payload, & curb weight?

A: GVWR is a combination of curb weight plus payload. Curb weight, sometimes called dry weight, is the empty weight of the vehicle/trailer. The payload is the amount of weight your vehicle/trailer can carry. An easy calculation to find your vehicle’s payload (how much cargo you can carry) is by taking the GVWR and subtracting the curb (empty) weight. The owner’s manual is also likely to have information about the GVWR, payload, and curb weight of the vehicle. The GVWR can also be found on your vehicle’s registration and title/certificate of origin.

Q: Why do I need to repack the bearings on my trailer?

A: To keep the bearings properly lubricated and keep the wheel turning freely. Even when your trailer is not in use, the grease breaks down from condensation in the bearings and causes corrosion to build up. If your bearings are not kept well-greased, the increased friction will eventually cause your wheel to seize and potentially cause the wheel to come off. The process of repacking the bearing includes: removing the hub, inspecting the brakes, cleaning out the old grease, inspecting and cleaning the bearings, replacing the grease, replacing the seals, and reassembling.

Q: How often do I need to repack the bearings on my trailer?

A: To keep your trailer well-maintained we recommend that you repack the bearings once per year or every 12,000 miles, whichever occurs first.

Q: Can you over grease/put too much grease in a trailer bearing?

A: Yes, Trailer bearings can be over greased. This can cause churning. Churning occurs when the bearing has to work much harder to push through the excess lubricant, which can result in energy loss and overheating. Over greasing your bearings can also result in excess pressure that can lead to a seal failure – which contaminates the brake linings.

Q: Do trailers have brakes?

A: Not all trailers are equipped with brakes. Only trailers with a GVWR greater than 3,000lbs. are required to have brakes.

Q: Do trailer brakes have a break-in period?

A: Yes, trailer brakes do have a break-in period. Brakes require a break-in period to achieve full performance. To break-in the brakes increase the gain on your trailer brake controller to the max level. Begin towing the trailer to speeds up to 40mph and then apply the brakes to reduce the speed to 20mph. Do not apply the brakes so hard that they lock up the trailer. Repeat this procedure 20 to 50 times until you can feel a noticeable difference in the brake performance. Safely pull over and check the brakes. DO NOT TOUCH THE BRAKES DIRECTLY. The brakes may smoke from the procedure and the area around the brakes should be hot.

If the brakes are not hot, verify that the wiring is properly connected and perform the break-in procedure again.

Q: What is the difference between spring vs torsion axle?

A: Torsion axles will give you a smoother ride when towing, are more rugged, and require less maintenance. Because they are mounted directly to the frame, torsion axles have fewer moving parts compared to spring suspensions. Leaf springs are less expensive and easier to repair/replace parts on.